Suitable for standard refrigerants, including. HFOs, R290 and R1270.

Shell and Tube condenser with finned tubes and shielding gas filling.

Maximum working pressure is 33 bar.

mounting brackets on the bottom and on the top front

seawater resistant version

EXPERT ADVICE

Professionals in refrigeration technology

SINCE 1986

Since 1986 in refrigeration technology

FACTORY GUARANTEE

You have Always genuine manufacturer's warranty

CUSTOMER SERVICE

info@mfmref.com

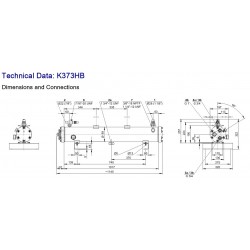

K373HB Bitzer condenser is a robust standard solution for seawater applications.

Bitzer K373HB is suitable for all common refrigerants (HFC, HFO, HFO / HFC blends) and there is a version approved for use with hydrocarbons (propane, propylene).

Thanks to the unique soldering process and the coating of the tube sheets, these K373HB condensers guarantee considerable reliability.

The low GWP profile of the heat exchanger tubes also ensures consistent performance over the entire service life of the K373HB condenser.

A desuperheater version is also available.

Suitable for standard refrigerants.

Shell and tube condenser with finned tubes, shielding gas free, entry.

Rotalock or soldering connection, soldering connection, flange with liquid output.

Rotalock valve with soldered connections, K123HB ... K4803TB with second liquid outlet (ships), right angle brackets above and below.

The K – B condensers, which can be easily installed on ships thanks to their compact length, set their own standard on the market for air conditioning in shipping and cooling with seawater.

Their unique soldering process and protective coating for tube sheets and water chambers ensure comprehensive reliability and consistent performance over the entire service life of the condenser.

The design enables low sea water flow rates to be maintained in the pipes, which is essential for marine applications.