Sight Glasses

Read more about sight glassesSGP16SN-FF Danfoss sight...

SGP19SN-FF Danfoss Sight...

SGP22SN-FF Danfoss Sight...

SGP6SN-MF Danfoss Sight...

SGP10SN-MF Danfoss Sight...

SGP12SN-MF Danfoss Sight...

SGP16SN-MF Danfoss Sight...

SGP22SN-MF Danfoss Sight...

SGP 1/2 RX Danfoss screw-in...

SGP 1/2 RN Danfoss screw-in...

SGP 3/4 RX Danfoss screw-in...

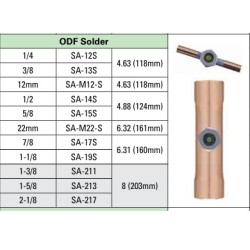

SA-12S Sporlan sight glass...

SA-12FM Sporlan sight glass...

SA-13S Sporlan sight glass...

SA-13FM Sporlan sight glass...

SA-14S Sporlan sight glass...

SA-14FM Sporlan sight glass...

SA-15S Sporlan sight glass...

SA-17S Sporlan sight glass...

SA-19S Sporlan sight glass...

SA-211 Sporlan sight glass...

SA-213 Sporlan sight glass...

SA-217 Sporlan sight glass...

Sight Glasses for refrigeration and freeze plants.

Series of sight glasses for high pressure applications (Max Working Pressure 52 bar/754 psig). are available in versions optimized for refrigerants with mineral oil e.g. HCFC, and in versions optimized for non-flammable HFC refrigerants. Sight glasses are available with flare, solder and socket connections, and with or without moisture indicators.

Sight glasses for food retail refrigeration also available with flare, solder and socket connections, and with moisture indicators. Or without moisture indicators.

Covers the full range of connection types used

Moisture Indicators are designed to monitor the moisture content within the liquid line of a refrigeration system.

Also series with stainless steel body and extended copper tube connections are fully hermetic products without the use of any gasket.

See-All moisture liquid indicator combines two functions of moisture and liquid indication into a single economical product. The indicator is a porous filter paper that is sensitive to moisture. A green dark color indicates the refrigerant is dry. A yellow color indicates the refrigerant is wet. The indicator is formulated so that it changes color at the moisture levels generally accepted as the safe operating range. Also, one can see through the sight glass to determine refrigerant is at the proper level in the liquid line to feed the expansion device. Each valve is factory tested to ensure positive leak-free performance.