Suitable for standard refrigerants, including. HFOs, R290 and R1270.

Shell and Tube condenser with finned tubes and shielding gas filling.

Maximum working pressure is 33 bar.

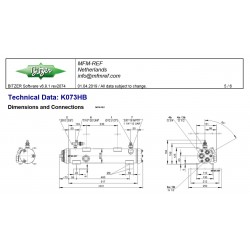

mounting brackets on the bottom and on the top front

seawater resistant version

EXPERT ADVICE

Professionals in refrigeration technology

SINCE 1986

Since 1986 in refrigeration technology

FACTORY GUARANTEE

You have Always genuine manufacturer's warranty

CUSTOMER SERVICE

info@mfmref.com

Seawater-resistant implementation: connection male thread

Shell and Tube condenser with finned pipes, protective gas charge, entrance.

Rotalock or soldering connection soldering connection, flange with fluid output.

Rotalock valve with solder connection, K123HB.. K4803TB with second fluid output (ships), right angle mounting brackets above and below.

Bitzer K073HB is Suitable for all commonly used refrigerants (HFC, HFO, HFC/HFO blends) and including a version approved for use with hydrocarbons (propane, propylene),

K073HB Bitzer condensers represent a standard and robust solution for seawater cooled applications.

These condenser K073HB ensure excellent reliability thanks to the unique tube-brazing process and the coating of the tube sheets.

While the use of a low-fouling design for the exchange tubes means that the K073HB condenser can deliver a consistent performance throughout its life.

The Bitzer Sea water cooled condensers have resistant design for seawater. They are proven over decades in all maritime applications.

The condensers are extremely corrosion-resistant to seawater. The low fouling profile tubes and the coating of tube sheets and coolant reversing covers make them the first choice.

A Bitzer seawater-cooled condenser is a type of heat exchanger used in refrigeration and air conditioning systems. It is designed to dissipate heat from the refrigerant in a cooling system by using seawater as the cooling medium. Seawater-cooled condensers are commonly used in marine applications, such as on ships and offshore platforms, where there is ready access to a source of seawater for cooling.

Here's how a Bitzer seawater-cooled condenser typically works:

Refrigerant Flow: The condenser receives hot, high-pressure refrigerant vapor from the compressor. This refrigerant carries heat absorbed from the space being cooled or from other sources.

Seawater Circulation: Seawater is drawn from the surrounding body of water, such as the ocean or a river, using a seawater pump. The seawater is then circulated through the condenser.

Heat Exchange: Inside the condenser, the hot refrigerant vapor is passed through a network of tubes or coils. These tubes or coils are in close contact with the seawater. As the refrigerant flows through these tubes, it releases heat to the surrounding seawater, causing the refrigerant to condense into a high-pressure liquid.

Cooling Effect: The seawater absorbs the heat from the refrigerant, causing it to warm up. The warmed seawater is then discharged back into the body of water.

Refrigerant Exit: After releasing heat and condensing into a liquid, the refrigerant exits the condenser and is typically sent to an expansion valve or an evaporator coil to continue the cooling cycle.

The use of seawater as a cooling medium in these condensers is advantageous in marine applications because it is readily available and provides efficient cooling. However, precautions must be taken to prevent corrosion of the condenser components due to the corrosive nature of seawater. This often involves the use of corrosion-resistant materials and regular maintenance to ensure the longevity and effectiveness of the condenser.

Bitzer is a well-known manufacturer of refrigeration and air conditioning equipment, including condensers, compressors, and other components used in various cooling systems. A Bitzer seawater-cooled condenser would be a condenser unit produced by the Bitzer company specifically designed for seawater cooling applications.